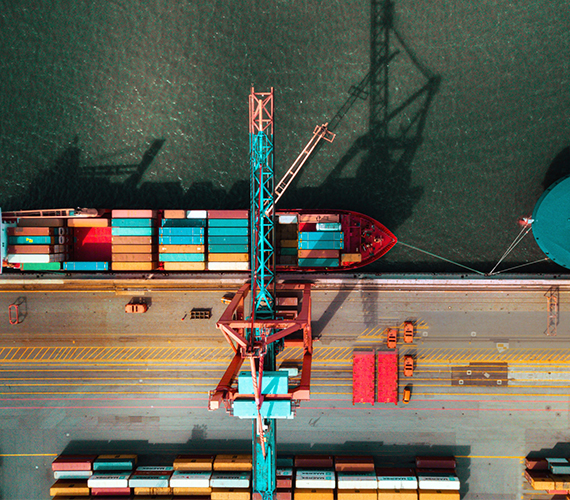

Nickel alloys are metals created by combining nickel with another material as the primary element. It combines two materials to produce more desirable properties like increased strength and corrosion resistance. It's used in a wide range of equipment across multiple industries due to its distinct properties. Apex Metal India is a leading supplier and stockiest of nickel in all grades.

Monel K500 is a nickel-copper alloy which combines the excellent corrosion resistance of Alloy 400 with higher strength and hardness obtained through the addition of aluminium and titanium to the nickel- copper base. It has excellent low temperature properties with tensile and yield strengths increasing with decrease in temperature, while ductility and toughness are virtually unimpaired. There is no ductile- to-brittle transformation even at temperatures as low as liquid hydrogen, making it suitable for cryogenic applications.

The corrosion resistance of Monel K500 is equivalent to that of Alloy 400 except that in the aged condition, it has a greater tendency towards stress-corrosion cracking in some environments. It is resistant to a sour gas environment and has very low corrosion rates in high velocity seawater, making it ideal for marine applications.

| C | Mn | Si | S | Ni | Cu | Ti | Ai | Fe | - | |

|---|---|---|---|---|---|---|---|---|---|---|

| Min | - | - | - | - | 63.0 | 27.00 | 0.35 | 2.3 | - | % |

| Max | 0.25 | 1.5 | 0.5 | 0.01 | - | 33.0 | 0.85 | 3.2 | 2.0 | % |

| Condition | Diameter Size Range | Tensile(PSI(MPA)) | Yield(0.2% offset),(PSI(MPA)Min) | Elongation in 2"or 4Dm in % | Reduction of Area | Rockwell Hardness HRC Max | Charpy Impacts at -29◦C (-20◦F) Joules (ftlb) |

|---|---|---|---|---|---|---|---|

| Cold worked and stress relieved | ≤25mm | 145,000 (1000) | 110,000 (760) | 14 | 40 | ||

| 26 ≤55mm | 140,000 (970) | 100,000 (690) | 16 | ||||

| Cold Worked, Solution Annealed and Aged | ≤25mm | 130,000 (900) | 90,000 (690) | 20 | 40 | ||

| 26 ≤55mm | 130,000 (900) | 85,000 (585) | 20 | ||||

| Hot worked and Aged | ≤110mm | 140,000 (970) | 100,000 (690) | 15 | 25 | 35 | Ave Min 27 (20) Ave Single 20 (15) |

| 111 ≤ 300mm | 120,000 (830) | 80,000 (550) | 15 | ||||

| Hot Worked, Solution Annealed and Aged | ≤25 mm | 130,000 (900) | 90,000 (620) | 20 | 25 | 35 | Ave Min 27 (20) Ave Single 20 (15) |

| 26 ≤110mm | 130,000 (900) | 85,000 (585) | 20 | ||||

| 110 ≤300mm | 120,000 (830) | 72,000 (500) | 15 |

| Melting Range | Room Temp Density | Young’s Modulus | Poisson’s Ratio (Aged) | Thermal Conductivity | Specific Heat (annealed) | Curie Temperature | Mean Coefficient of expansion Annealed 20-100°C (70-212°F) | Magnetic Permeability @ 200 Oersted (Hot worked and aged) |

|---|---|---|---|---|---|---|---|---|

| 1315°C - 1350°C (2400°F- 2460°F) | 8.44 g/cm ³ (0.305 lb/in ³) | 179 x 10ᶟ MPa | 0.32 | 17.2 W/m. °C | 418.7 Joules/kg°C | -90°C (-130°F) | 13.4 x 10-⁶ | 1.0018 |