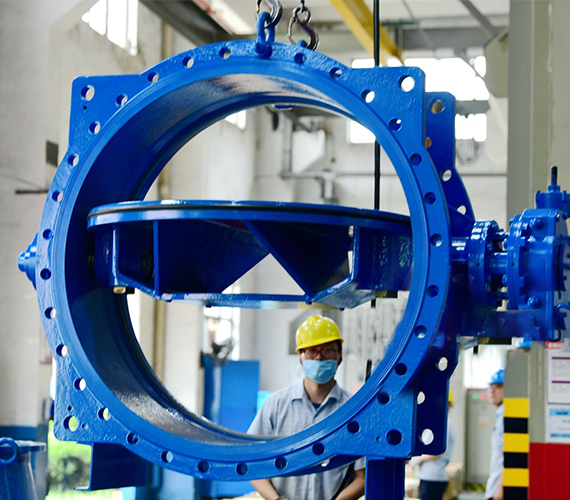

Nickel alloys are metals created by combining nickel with another material as the primary element. It combines two materials to produce more desirable properties like increased strength and corrosion resistance. It's used in a wide range of equipment across multiple industries due to its distinct properties. Apex Metal India is a leading supplier and stockiest of nickel in all grades.

MONEL- 400 has a wide range of mechanical properties, depending on the supply condition, with excellent properties at sub-zero temperatures. It does not undergo a ductile-to-brittle transition even when cooled to the temperature in liquidity drogen. It also has useful short-time high temperature properties in the hot rolled and annealed condition and toughness is maintaine dover a widerange of temperatures.

Due to MONEL- 400's resistance to corrosion by many reducing media,it makes it suitable for service in a variety of environment sand is widely used in marine applications due to it's very low corrosion rates in flowing sea water. It is also resistant to stress corrosion cracking and pitting in most fresh and industrial waters.

| Element | Min | Max |

|---|---|---|

| C | - | 0.03 |

| Mn | - | 2.0 |

| Si | - | 0.5 |

| S | - | 0.024 |

| Ni | 63.0 | - |

| Cu | 28.0 | 34.0 |

| Fe | - | 2.5 |

| - | % | % |

| Condition | Tensile(PSI(MPA)) | Yield(0.2% offset),(PSI(MPA)Min) | Elongation in 2"or 4Dm in % | Elongation 5.65√S0 min % | Rockwell Hardness HRC Max | |

|---|---|---|---|---|---|---|

| Hot worked and annealed | 70,000 (483) | 25,000 (172) | 35 | 35 | 35 | |

| Cold worked and stress relieved | ≤40 mm dia | 87,000 (600) | 60,000 (415) | 22 | 20 | 35 |

| >40mm ≤ 55mm dia | 84,000 (580) | 55,000 (380) |