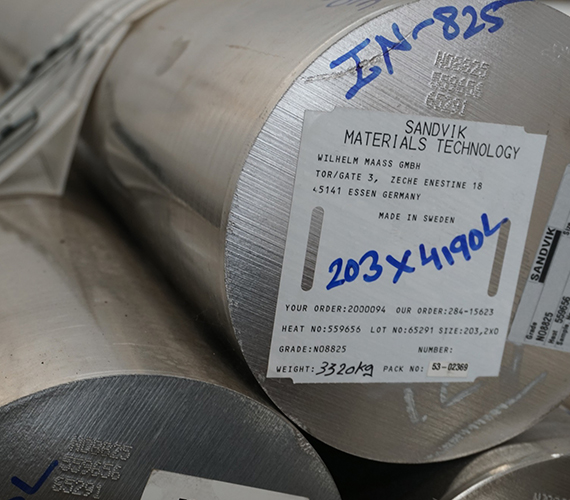

Nickel alloys are metals created by combining nickel with another material as the primary element. It combines two materials to produce more desirable properties like increased strength and corrosion resistance. It's used in a wide range of equipment across multiple industries due to its distinct properties. Apex Metal India is a leading supplier and stockiest of nickel in all grades.

Alloy 825 is a nickel-iron-chromium alloy that resists general corrosion, pitting and crevice corrosion, intergranular corrosion and stress corrosion cracking. Additions of molybdenum and copper resist reducing agents and acids. Nickel levels are sufficient for resistance to chloride-ion stress-corrosion cracking. Molybdenum aids resistance to pitting and crevice corrosion. Chromium provides resistance to oxidising conditions and titanium stabilises the alloy against sensitization to intergranular corrosion.

Alloy 825 has good mechanical properties from cryogenic to moderately high temperatures around 540°C. It also has good impact strength at room temperature and retains its strength at cryogenic temperatures. This alloy can be strengthened substantially by cold working.

| C | Mn | Si | S | Cr | Ni | Cu | Ti | Ai | Mo | Fe | - | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | - | - | - | - | 19.5 | 38.0 | 1.5 | 0.6 | - | 2.5 | 22.0 | % |

| Max | 0.05 | 1.0 | 0.5 | 0.03 | 23.5 | 46.5 | 3.0 | 1.2 | 0.2 | 3.5 | - | % |

| Tensile PSI (MPA) min | Yield (0.2% offset), PSI (MPA) Min | Elongation in 2" or 4D min% | Hardness Rockwell Max |

|---|---|---|---|

| 85,000 (586) | 35,000 (241) | 30 | 35 (hardness is typically 200-240 HBW - if used for seals 160HBW max) |