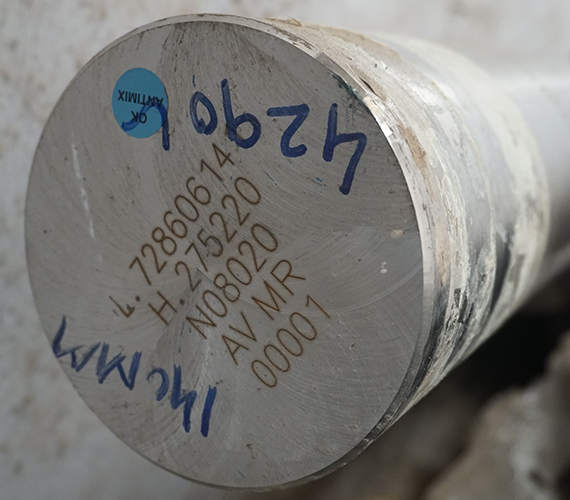

Nickel alloys are metals created by combining nickel with another material as the primary element. It combines two materials to produce more desirable properties like increased strength and corrosion resistance. It's used in a wide range of equipment across multiple industries due to its distinct properties. Apex Metal India is a leading supplier and stockiest of nickel in all grades.

Nickel alloy 20 is a low-carbon, niobium-stabilized austenitic nickel/iron/chromium alloy with additions of molybdenum and copper. It exhibits exceptional corrosion resistance in chemical environments containing phosphoric acid, nitric acid, chlorides and sulphuric acid. It also has good mechanical properties at both ambient and elevated temperatures.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod

tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam,

quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo

consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse

cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non

proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

The chemical composition nickel alloy 20 is outlined in the following table.

| Element | Iron, Fe | Nickel, Ni | Chromium, Cr | Copper, Cu | Manganese, Mn | Molybdenum, Mo | Niobium, Nb | Silicon, Si | Carbon, C | Phosphorous, P | Sulfur, S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 35 | 32-38 | 19-21 | 3-4 | ≤2 | 2-3 | ≤1 | ≤1 | ≤0.07 | ≤0.045 | ≤0.035 |

The mechanical properties of nickel alloy 20 are displayed in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength (annealed) | 620 MPa | 89900 psi |

| Yield strength (annealed) | 300 MPa | 43500 psi |

| Elongation at break (annealed) | 41% | 41% |

The following are the list of applications of nickel 205 alloy: