Nickel alloys are metals created by combining nickel with another material as the primary element. It combines two materials to produce more desirable properties like increased strength and corrosion resistance. It's used in a wide range of equipment across multiple industries due to its distinct properties. Apex Metal India is a leading supplier and stockiest of nickel in all grades.

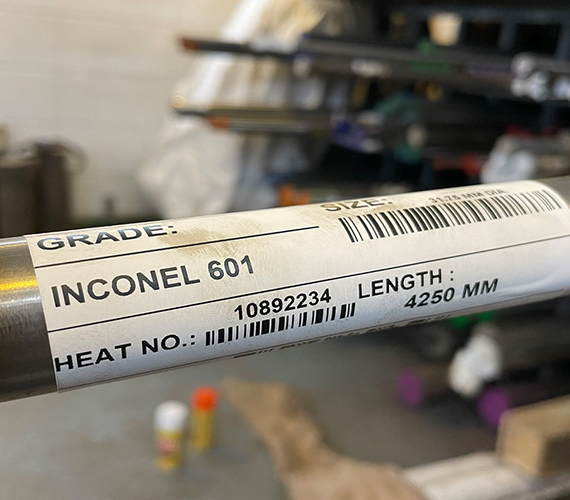

Inconel 601 nickel-chromium-iron alloy is a general-purpose engineering material for applications that require resistance to heat and corrosion. The outstanding characteristic of Inconel 601 is its resistance to high-temperature oxidation. The alloy also has good resistance to aqueous corrosion, has high mechanical strength, and is readily formed, machined, and welded.

The limiting chemical composition of Inconel 601 is listed in Table 1. The composition is a face-centered-cubic solid solution with a high degree of metallurgical stability. The alloy’s nickel base, in conjunction with a substantial chromium content, provides resistance to many corrosive media and high-temperature environments. Oxidation resistance is further enhanced by the aluminum content.

| - | Ni | Cr | C | Mn | Si | S | Fe |

|---|---|---|---|---|---|---|---|

| Max | 63.0 | 25.0 | 0.10 | 1.0 | 1.0 | 0.015 | Bal |

| Min | 58.0 | 21.0 |

| Ultimate Tensile | Yield Strength (0.2% OS) | Elong. in 2 in. or 50mm or 4D, min., % | R/A | Hardness | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cold Worked/As worked | |||||||||||

| Min | 80 KSi | 30 KSi | 30 | ||||||||

| Max | |||||||||||

| Min | 550 MPa | 205 MPa | |||||||||

| Max | |||||||||||

| Hot Worked/As Worked | |||||||||||

| Min | 80 KSi | 30 KSi | 30 | ||||||||

| Max | |||||||||||

| Min | 550 MPa | 205 MPa | |||||||||

| Max | |||||||||||