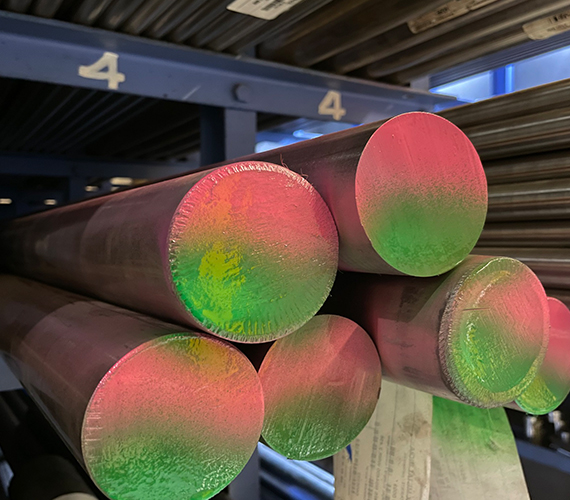

Nickel alloys are metals created by combining nickel with another material as the primary element. It combines two materials to produce more desirable properties like increased strength and corrosion resistance. It's used in a wide range of equipment across multiple industries due to its distinct properties. Apex Metal India is a leading supplier and stockiest of nickel in all grades.

Inconel 925 is an age hardenable nickel-iron-chromium alloy with the additions of molybdenum, copper, titanium and aluminium. The alloy’s chemical composition is designed to provide a combination of high strength and excellent corrosion resistance. The nickel content provides protection against chloride-iron stress corrosion cracking and in combination with molybdenum and copper, gives outstanding resistance to reducing chemicals. Molybdenum aids resistance to pitting and crevice corrosion, while chromium provides resistance to oxidising environments. Titanium and aluminium form part of the precipitation hardening reaction that greatly increases hardness and strength of the alloy.

The alloy has a high level of corrosion resistance and resists general corrosion, pitting, crevice, intergranular corrosion and stress corrosion cracking. It is particularly useful in sour (H2S containing) crude oil, natural gas, sulphuric acid, phosphoric acid and seawater.

| C | Mn | P | S | Si | Ni | Cr | Mo | Ai | Ti | Nb | Cu | Fe | - | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | - | - | - | - | - | 42.0 | 19.5 | 2.5 | 0.1 | 1.9 | - | 22.0 | 1.5 | % |

| Max | 0.03 | 1.0 | 0.03 | 0.03 | 0.5 | 46.0 | 22.5 | 3.5 | 0.5 | 2.4 | 0.5 | - | 3.0 | % |

| Tensile PSI (MPA) min | Yield (0.2% offset), PSI (MPA) Min | Elongation in 2" or 4D min% | Reduction of Area min% | Charpy Impacts at - 60◦C (-75◦F)J (ftlb) | Rockwell hardness HRC |

|---|---|---|---|---|---|

| 140,000 (965) | 110,000 (758) | 18 | 20 | Single Min 43(32) Average min 47 (35) | 30-38 |

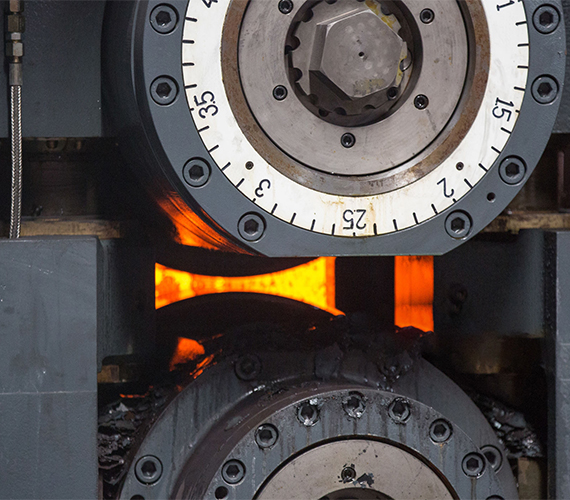

Incoloy 925 is ideally suited to down-hole and surface gas well components such as :